By Greg Holbrook, PE

David Lattanzi, PhD, PE is an Assistant Professor at George Mason University, specializing in robotics, 3D visualization, and artificial intelligence as it relates to Civil and Structural Engineering. He presented at the annual Pittsburgh SEI Chapter and ABCD Organization joint meeting on these topics and how they are changing the industry.

David Lattanzi, PhD, PE is an Assistant Professor at George Mason University, specializing in robotics, 3D visualization, and artificial intelligence as it relates to Civil and Structural Engineering. He presented at the annual Pittsburgh SEI Chapter and ABCD Organization joint meeting on these topics and how they are changing the industry.

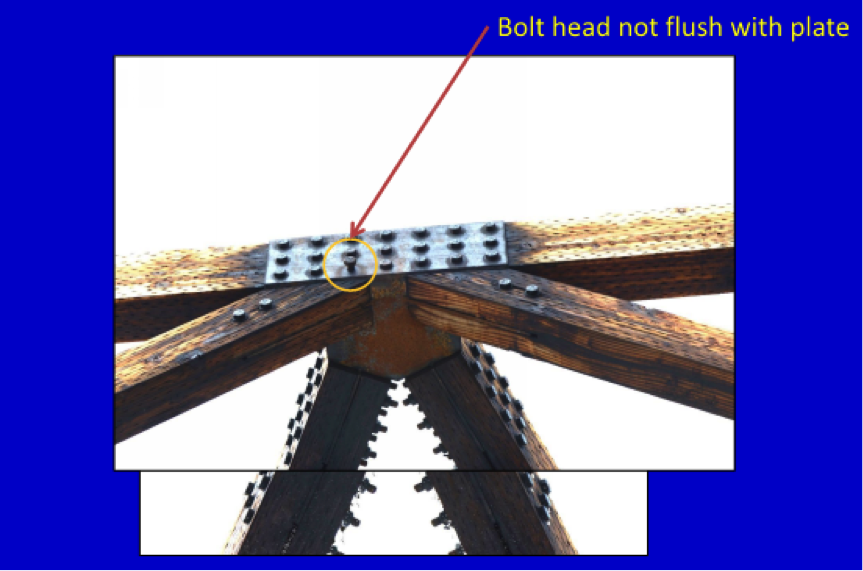

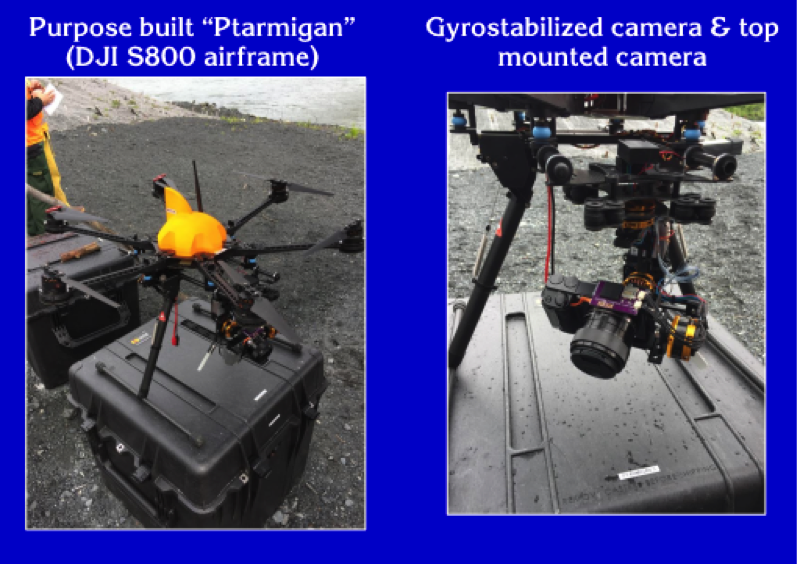

One emerging technology is the use of Unmanned Aerial Vehicles (UAVs), commonly known as drones, to assist with the inspection, analysis, and review of structures during most phases of construction and maintenance. A camera or similar recording device can be connected to a drone to capture video of the entire structure from multiple angles as the UAV is flown around the structure. The recorded data is detailed enough to review individual images of small components such as bolted connections, as well as larger components such as steel or concrete girders. Additionally, the data can be processed to develop 3D point clouds of the entire structure. With this information, one can review overall dimensions, full-system interaction, and potential structural defects. The user also has the ability to zoom into select details of the structure and access the pictures taken from the drone at that specific location.

Dr. Lattanzi also shared some lessons learned while conducting a case study using UAVs to analyze a bridge or structure. First, planning is key. The team quickly determined that having a plan of the expected flight routes and the camera views/orientations was extremely important. To capture all the components of the structure and make a complete 3D model requires overlapping images from multiple angles and directions. Another lesson learned was that communication between team members is extremely important, both during the inspection and while manipulating the data to create the 3D model. Finally, the entire team agreed that one thing is certain: Inspectors aren’t being displaced anytime soon. For inspectors and engineers, drones are a new tool and the data they provide is the product. UAVs can capture data, but inspectors are required to understand the photo content and determine the importance and requirement for additional analysis or repair. This is similar to how engineers have come to embrace computers and technology for assistance in designing structures. Computers don’t design an entire structure; design requires input and judgement from an engineer to determine what is appropriate and how to analyze the output .

Dr. Lattanzi also shared some lessons learned while conducting a case study using UAVs to analyze a bridge or structure. First, planning is key. The team quickly determined that having a plan of the expected flight routes and the camera views/orientations was extremely important. To capture all the components of the structure and make a complete 3D model requires overlapping images from multiple angles and directions. Another lesson learned was that communication between team members is extremely important, both during the inspection and while manipulating the data to create the 3D model. Finally, the entire team agreed that one thing is certain: Inspectors aren’t being displaced anytime soon. For inspectors and engineers, drones are a new tool and the data they provide is the product. UAVs can capture data, but inspectors are required to understand the photo content and determine the importance and requirement for additional analysis or repair. This is similar to how engineers have come to embrace computers and technology for assistance in designing structures. Computers don’t design an entire structure; design requires input and judgement from an engineer to determine what is appropriate and how to analyze the output .

While it is encouraging that the industry embrace UAVs to streamline the construction and inspection processes there is still an uphill battle before full implementation can be achieved. First and foremost, there are a lot of regulations limiting where flights are allowed and how UAVs are used in the field and on construction sites. Additionally, measurements of defects can be estimated from images and data, but actual physical testing (such as hammer sounding, chloride tests, field measurements of cracks) can’t be accomplished. Furthermore, until operators have more experience and better understanding of the required process and approach to use while recording video and data, there is the potential that certain items may be missed that would have been found if inspectors physically reviewed all the connections and members in person.

While it is encouraging that the industry embrace UAVs to streamline the construction and inspection processes there is still an uphill battle before full implementation can be achieved. First and foremost, there are a lot of regulations limiting where flights are allowed and how UAVs are used in the field and on construction sites. Additionally, measurements of defects can be estimated from images and data, but actual physical testing (such as hammer sounding, chloride tests, field measurements of cracks) can’t be accomplished. Furthermore, until operators have more experience and better understanding of the required process and approach to use while recording video and data, there is the potential that certain items may be missed that would have been found if inspectors physically reviewed all the connections and members in person.

The presentation served to bring awareness to the use of UAVs and the data they collect to structural engineers, inspectors, and contractors who may be considering using drones to streamline inspections and construction for upcoming projects. This is just an overview of some of the benefits and limitations of UAVs in the construction industry. It is important to contact trained professionals that are knowledgeable in the use of UAVs when determining the applicability for a project and the appropriate information required to make its use successful.

The presentation served to bring awareness to the use of UAVs and the data they collect to structural engineers, inspectors, and contractors who may be considering using drones to streamline inspections and construction for upcoming projects. This is just an overview of some of the benefits and limitations of UAVs in the construction industry. It is important to contact trained professionals that are knowledgeable in the use of UAVs when determining the applicability for a project and the appropriate information required to make its use successful.