By: Greg Holbrook, P.E.

Approximately 80 members and guests attended the Annual Joint Dinner between The Pittsburgh Association for Bridge Construction & Design (ABCD) and the ASCE Pittsburgh Section SEI Chapter at Cefalo’s Banquet and Event Center in Carnegie on January 21, 2016.

Approximately 80 members and guests attended the Annual Joint Dinner between The Pittsburgh Association for Bridge Construction & Design (ABCD) and the ASCE Pittsburgh Section SEI Chapter at Cefalo’s Banquet and Event Center in Carnegie on January 21, 2016.

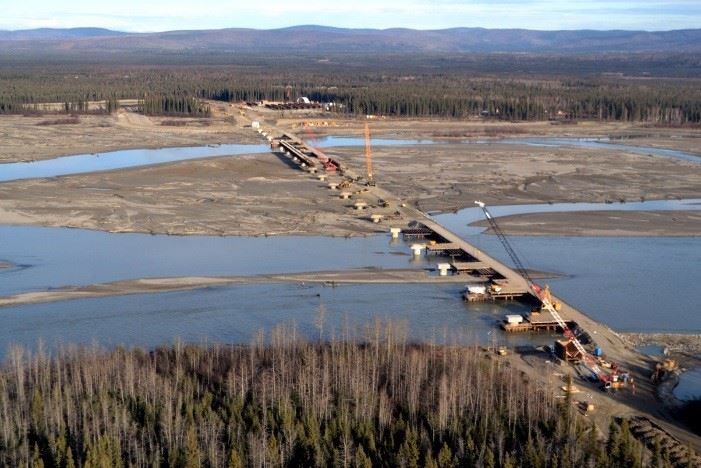

The technical presentation of the evening was the “Design and Construction of the Tanana River Bridge” located near Salcha, Alaska.

Robert Stachel, P.E., Executive Vice President of HRV Inc., discussed the challenging characteristics of the design and construction of this bridge.

The Tanana River Bridge is Alaska’s longest bridge at 3,300 ft in length, and cost $188 Million for design and construction. The bridge, owned by the Alaska Railroad, consists of over 20 structural steel 165 ft. long spans. The structure provides the military with year-round ground access to training ranges and to supply fuel to bases in the future.

Mr. Stachel focused on the unusual fabrication of the structure. With a winning bid from an Asian fabricator, the design and construction team traveled across the Pacific to witness the magnitude of fabrication opportunities that the Asian market has to offer; economies of scale, high-tech equipment, new facilities, etc. Attendees became acutely aware of the necessity for equipment and facilities of this nature in the United States to compete with global steel fabricators and manufacturers. In this case, the fabricator for the Tanana River Bridge constructed a new facility specifically for this project with state-of-the-art equipment and QA/QC measures.

Mr. Stachel also discussed the challenge of transporting the components and construction on a remote site. After shipping the components of the superstructure to Alaska without issue, the team then had the task of transporting the components from the coast to the project site. This meant moving large members on trucks, traveling down highways and roadways with little traction, or in some cases completely ice covered roads (think Ice Road Truckers!). In one instance a steel girder fell off the bed of the truck and sat off to the side of the road, contorted in many directions, for a lengthy amount of time before being able to be hoisted back onto a truck and continuing to the site. After much professional discussion and testing, this specific girder was determined to be straight and usable in the final structure.

Mr. Stachel also discussed the challenge of transporting the components and construction on a remote site. After shipping the components of the superstructure to Alaska without issue, the team then had the task of transporting the components from the coast to the project site. This meant moving large members on trucks, traveling down highways and roadways with little traction, or in some cases completely ice covered roads (think Ice Road Truckers!). In one instance a steel girder fell off the bed of the truck and sat off to the side of the road, contorted in many directions, for a lengthy amount of time before being able to be hoisted back onto a truck and continuing to the site. After much professional discussion and testing, this specific girder was determined to be straight and usable in the final structure.

Additional project challenges stemmed from the sub-zero temperatures, including difficulties driving sheet piles into frozen ground, causing them to bend at shallow depths. Additional factors not normally seen on construction projects here in the Pittsburgh Area included weather related welding issues and issues for construction workers on site.

The social hour for colleagues and professionals to interact continued to the dinner hour.

Attendees earned 1.0 Professional Development Hour (PDH).

We extend appreciation to Robert Stachel, P.E. and HRV Inc. for sharing their knowledge and experience, and the joint efforts of all ABCD & Pittsburgh SEI Chapter committee members and leadership for their work on another successful Joint Dinner opportunity for Civil Engineer members to build and maintain technical and professional skills.